The Lean Efficiency Framework optimizes workplace organization and productivity through lean management principles initially developed for manufacturing. Key components include 5S training: sorting, setting in order, cleaning (shining), standardizing, and sustaining improvements. This transforms workplaces, enabling process standardization that leads to consistency, reduced errors, improved quality, and faster cycles. By fostering a culture of continuous improvement, every employee contributes to identifying inefficiencies, driving sustained performance enhancements, and providing businesses with a competitive edge through streamlined operations.

“Unleash the power of efficiency with our comprehensive guide to the Lean Efficiency Framework. Discover how this proven system transforms workplaces, enhancing productivity and quality of life for employees. We explore key components like 5S Training, a structured approach to workplace organization, and Continuous Improvement as the heart of lean management. Learn effective strategies for Process Standardization, ensuring consistent results. By implementing these principles, organizations can achieve remarkable efficiency gains.”

- Understanding the Lean Efficiency Framework: A Comprehensive Guide

- Implementing 5S Training for Optimal Workplace Organization

- Continuous Improvement and Process Standardization in Lean Management

Understanding the Lean Efficiency Framework: A Comprehensive Guide

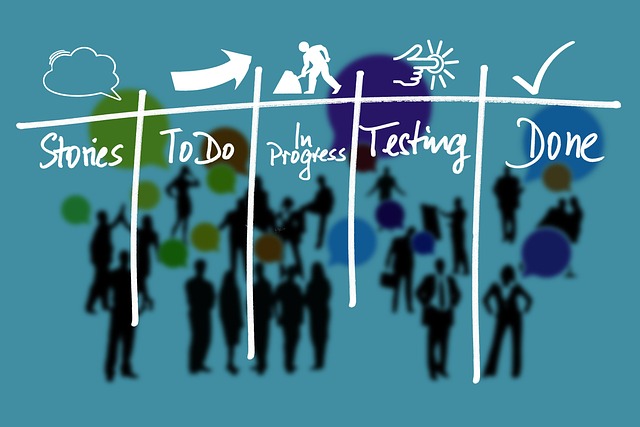

The Lean Efficiency Framework is a powerful system designed to optimize workplace organization and enhance productivity through continuous improvement. At its core, it revolves around the concept of eliminating waste and maximizing value in various processes. This framework has its roots in lean management principles, which originated from manufacturing industries aiming to streamline production lines. One key component driving this methodology is 5S training—a set of practices focusing on sorting, setting in order, shining (cleaning), standardizing, and sustaining these improvements. By implementing 5S, organizations can achieve a highly organized and efficient workplace, laying the foundation for further lean transformations.

Process standardization plays a pivotal role in this framework. It involves defining, documenting, and optimizing workflows to ensure consistency and reduce variations. This standardization facilitates better control over processes, enabling faster cycles, fewer errors, and improved quality. As organizations embrace lean management principles, they encourage a culture of continuous improvement where every employee contributes to identifying inefficiencies and implementing solutions. This collaborative approach drives sustained performance enhancements, making the Lean Efficiency Framework a valuable tool for businesses seeking to gain a competitive edge through streamlined operations.

Implementing 5S Training for Optimal Workplace Organization

Implementing 5S Training is a powerful strategy for achieving optimal workplace organization within the framework of lean management. This method, rooted in Japanese lean manufacturing practices, focuses on creating an environment that enhances efficiency and productivity through process standardization. By teaching employees the principles of Sort, Set in Order, Shine (Clean), Standardize, and Sustain (5S), organizations can drive significant improvements in workplace layout and overall workflow.

The 5S continuous improvement approach ensures that each step is thoroughly understood and consistently applied. Training sessions should cover how to identify and remove waste, organize tools and equipment, maintain a clean and safe space, establish standardized procedures, and continuously monitor and improve the system. This holistic training empowers employees to take ownership of their workspace, fostering a culture of accountability and enhancing overall team performance.

Continuous Improvement and Process Standardization in Lean Management

In lean management, Continuous Improvement (Kaizen) is a core principle that drives organizational success. It involves fostering a culture where every employee actively participates in identifying and eliminating waste, streamlining processes, and enhancing productivity. This approach encourages regular reviews and adjustments to work practices, ensuring that the organization constantly evolves and adapts to changing market demands. By integrating 5S training into daily operations, lean management promotes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices.

Process Standardization is another vital aspect of lean efficiency. It involves defining and documenting standard work procedures to ensure consistency and quality across the organization. This standardization allows for better control, easier training, and faster problem-solving as employees can refer to clear guidelines. When combined with 5S continuous improvement initiatives, process standardization helps maintain a tidy, efficient workspace, reduces errors, and enhances overall productivity, ultimately contributing to the ongoing success of any business.