The Lean Efficiency Framework, powered by lean manufacturing principles, optimizes workplace performance through the elimination of waste and maximization of value. Central to this framework is the 5S training method (Sort, Set in Order, Shine, Standardize, Sustain), promoting systematic organization. By implementing these practices, organizations achieve enhanced efficiency, error reduction, and continuous improvement. Lean management advocates for process standardization, enabling swift responses to market demands and gains in productivity, employee engagement, and operational excellence through the 5S methodology. This data-driven approach, proven successful across diverse industries, fosters workplace organization, empowers employees, and drives long-term success.

“Unleash the power of efficiency with a deep dive into the Lean Efficiency Framework – a game-changer for modern workplaces. This comprehensive guide explores the core principles of lean management and its profound impact on workplace organization. Discover how the 5S training methodology standardizes processes, enhances continuous improvement, and leverages data feedback loops. From real-world applications to success stories, learn how organizations have transformed their operations through lean practices, achieving optimal efficiency.”

- Understanding Lean Efficiency Framework: A Comprehensive Overview

- The Core Principles of Lean Management and Its Impact on Workplace Organization

- Unveiling the 5S Training Methodology: A Step-by-Step Guide to Process Standardization

- Continuous Improvement in Action: Strategies for Sustaining Lean Practices

- Leveraging Data and Feedback Loops for Optimal Workplace Efficiency

- Real-World Applications: Success Stories of Implementing Lean Efficiency Frameworks

Understanding Lean Efficiency Framework: A Comprehensive Overview

The Lean Efficiency Framework is a powerful approach to optimizing workplace performance and productivity. At its core, it revolves around the principle of eliminating waste and maximizing value in various business processes. This framework draws heavily from lean management concepts, which originated in manufacturing but have since been applied across diverse industries. One of the key components is the 5S training method—a systematic process for organizing the workplace, involving Sort, Set in Order, Shine (cleanliness), Standardize, and Sustain. By implementing these principles, employees can create an environment conducive to improved efficiency and reduced errors.

Lean management advocates for continuous improvement through a structured approach. Process standardization plays a pivotal role here, ensuring that tasks are executed consistently without unnecessary variations. This not only enhances quality but also streamlines operations, allowing organizations to respond swiftly to changing market demands. The 5S continuous improvement methodology encourages regular assessments and adjustments, fostering a culture of ongoing optimization. Through these practices, businesses can achieve remarkable gains in productivity, employee engagement, and overall operational excellence.

The Core Principles of Lean Management and Its Impact on Workplace Organization

Lean management is a powerful framework that focuses on maximizing efficiency and minimizing waste in the workplace. Its core principles are deeply rooted in the Japanese concept of Lean, aiming to create fluid, continuous processes by eliminating non-value-added activities. These fundamentals emphasize the importance of understanding customer needs, streamlining workflows, empowering employees, and fostering a culture of continuous improvement. One key component is the 5S training method—Sort, Set in Order, Shine (clean), Standardize, and Sustain—which teaches organizations to organize their spaces and processes effectively, ensuring everything has its place and purpose.

By implementing lean management practices, workplace organization undergoes a transformative shift. It encourages businesses to rethink traditional organizational structures, promoting cross-functional collaboration and breaking down silos. Process standardization becomes a cornerstone, enabling teams to work cohesively, reducing errors, and enhancing overall productivity. This approach has a ripple effect, improving employee morale, satisfaction, and engagement as they become active participants in identifying and implementing improvements, ultimately driving business success and competitiveness in today’s market.

Unveiling the 5S Training Methodology: A Step-by-Step Guide to Process Standardization

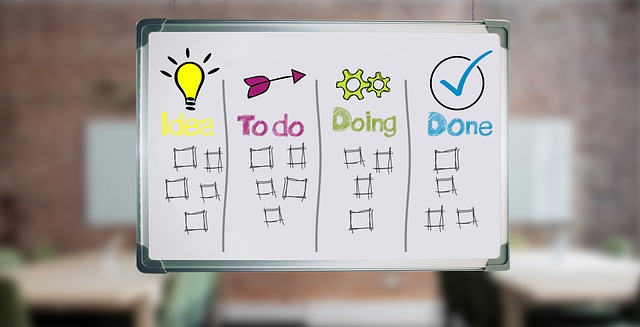

Unveiling the 5S Training Methodology is a crucial step in implementing lean efficiency frameworks and driving workplace organization. This powerful tool, rooted in lean management principles, offers a structured approach to process standardization—a key aspect of continuous improvement initiatives. The 5S method involves five distinct steps, each designed to create a clean, safe, and efficient workspace.

The first two steps, Sort and Set in Order, focus on decluttering and organizing physical spaces. Next, Shine emphasizes thorough cleaning and maintenance, ensuring every tool and machine is in optimal condition. Standardize then establishes consistent procedures for tasks, while Sustain serves as the foundation for continuous improvement, fostering a culture of ongoing optimization. By following this step-by-step guide, organizations can effectively transform their work environments into streamlined, high-performance systems.

Continuous Improvement in Action: Strategies for Sustaining Lean Practices

In the realm of lean efficiency framework, continuous improvement is a cornerstone principle that drives organizational success. Implementing and sustaining lean practices requires a dynamic approach where every opportunity for enhancement is embraced. One powerful strategy to achieve this is through 5S training—a structured methodology focusing on workplace organization, process standardization, and continuous improvement. This involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke). By instilling these principles, organizations can create a culture of efficiency where every employee actively contributes to streamlining operations and eliminating waste.

To maintain momentum, lean management should foster an environment that encourages ongoing evaluation and refinement. Regular reviews, performance metrics, and feedback loops play a pivotal role in identifying areas for improvement. This proactive mindset ensures that the organization remains agile and responsive to changing market dynamics. By integrating 5S continuous improvement into day-to-day operations, businesses can achieve remarkable gains in productivity, quality, and overall workplace satisfaction.

Leveraging Data and Feedback Loops for Optimal Workplace Efficiency

In the realm of lean efficiency frameworks, leveraging data and feedback loops is a game-changer for workplace optimization. Organizations employing 5S training and lean management principles understand the power of structured data collection and continuous improvement. By implementing 5S continuous improvement methodologies, such as regularly conducting 5S audits and utilizing visual management tools, businesses can achieve remarkable workplace organization. This involves process standardization, ensuring every task is streamlined and optimized for efficiency.

Data-driven insights enable managers to identify bottlenecks, inefficiencies, and areas for process refinement. Feedback loops facilitate a culture of continuous learning where employee suggestions are actively sought and implemented. This collaborative approach not only enhances overall workplace organization but also fosters innovation and empowers employees to take ownership of their roles. As a result, organizations can achieve significant improvements in productivity, quality, and customer satisfaction.

Real-World Applications: Success Stories of Implementing Lean Efficiency Frameworks

In today’s competitive business landscape, organizations are constantly seeking ways to enhance efficiency and productivity. One proven approach that has gained significant traction is the Lean Efficiency Framework, rooted in lean management principles. This framework focuses on streamlining processes, eliminating waste, and fostering continuous improvement, all of which contribute to a more organized and effective workplace. One of the key components driving this success is 5S training—a systematic method for workplace organization that involves sorting, setting in order, shining (cleaning), standardizing, and sustaining.

Successful implementation of lean management techniques has been documented across various industries. For example, manufacturing companies have achieved remarkable results through process standardization and 5S continuous improvement initiatives. By applying these principles, they’ve not only improved production efficiency but also enhanced product quality and reduced operational costs. Similarly, service-oriented businesses have leveraged lean methods to optimize their operations, leading to better customer satisfaction and increased profitability. These real-world applications underscore the versatility and effectiveness of the Lean Efficiency Framework in transforming organizations and driving long-term success.