5S training, rooted in Japanese manufacturing, is a lean management approach that optimizes workplace organization and continuous improvement. Through sorting, setting in order, cleaning, standardizing, and sustaining, organizations transform chaotic spaces into efficient operations, eliminating waste and fostering a culture of discipline. This methodology boosts productivity, enhances process standardization, and promotes innovation, making it a powerful tool for today's competitive business landscape.

Enhancing productivity is a key driver for any successful organisation. In this article, we explore a comprehensive approach focused on four core pillars: Understanding the Foundation with 5S Training and its role in productivity; adopting Lean Management Principles for streamlined workflows; implementing effective Workplace Organization strategies; and fostering 5S Continuous Improvement through a cycle of refinement. Additionally, we delve into Process Standardization as the key to maintaining consistency and quality across operations.

- Understanding the Foundation: 5S Training and Its Role in Productivity

- Lean Management Principles for Streamlined Workflows

- Workplace Organization: Strategies for Efficient Space Utilization

- 5S Continuous Improvement: A Cycle of Refinement

- Process Standardization: The Key to Consistency and Quality

Understanding the Foundation: 5S Training and Its Role in Productivity

Understanding the Foundation: 5S Training and Its Role in Productivity

In today’s competitive business landscape, maximizing productivity is paramount for success. A powerful tool that has gained prominence in lean management is 5S training, a methodology rooted in workplace organization and continuous improvement. This approach, derived from Japanese manufacturing practices, aims to create an efficient and safe work environment by standardizing processes and minimizing waste. By embracing 5S principles, organizations can transform their spaces into streamlined, productive hubs.

The 5S framework involves sorting (identifying and retaining only essential items), setting in order (arranging tools and equipment logically), shining (cleaning and maintaining the workspace), standardizing (establishing consistent procedures), and sustaining (continuing the cycle of improvement). This systematic approach not only enhances productivity but also fosters a culture of quality and continuous learning. Effective 5S training empowers employees to take ownership of their work areas, leading to increased efficiency and overall organizational success.

Lean Management Principles for Streamlined Workflows

In today’s fast-paced business environment, maintaining a lean and efficient workflow is crucial for productivity enhancement. Lean Management, a philosophy initially developed by Toyota, focuses on eliminating waste and maximizing value in processes. One powerful tool within this framework is 5S training, which involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these principles, organizations can achieve remarkable workplace organization and continuous improvement.

5S continuous improvement drives process standardization by encouraging a culture of orderliness and discipline. Each ‘S’ represents a step towards a more streamlined and effective operation. Sorting involves removing clutter and unnecessary items, setting in order ensures everything has its place, shining promotes a clean and safe environment, standardizing establishes consistent procedures, and sustaining focuses on maintaining these practices over time. This method enhances productivity by reducing wasted time and effort, thereby fostering an efficient and productive work environment.

Workplace Organization: Strategies for Efficient Space Utilization

Workplace Organization plays a pivotal role in enhancing productivity. One proven approach is adopting 5S training principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This lean management methodology ensures every item in the workplace has its designated place, streamlining operations and reducing wasted time and resources. By implementing 5S continuous improvement practices, organizations can create an environment that fosters efficiency and focus.

Process standardization is another key strategy within workplace organization. This involves establishing clear procedures for routine tasks, ensuring consistency and minimizing errors. Standardized processes not only improve productivity but also enable employees to quickly adapt to changes, promoting a flexible yet structured work environment. Together, these strategies contribute to optimal space utilization, making the most of available resources and driving overall operational excellence.

5S Continuous Improvement: A Cycle of Refinement

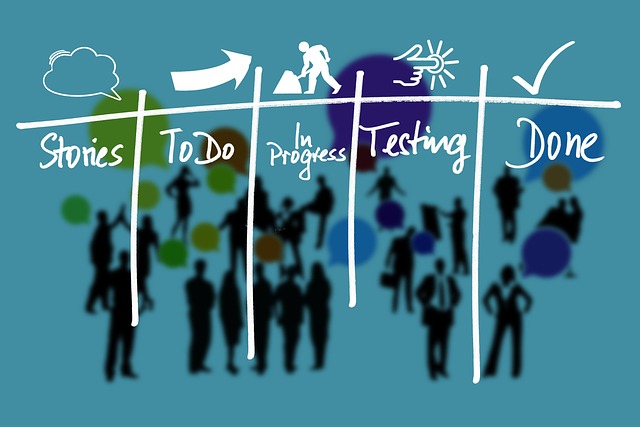

The 5S Continuous Improvement method is a powerful approach to enhancing productivity and workplace organization, rooted in lean management principles. This methodology involves a cyclical process of refinement, where each ‘S’ represents a step: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By following these stages, organizations can transform their workspace and work processes. 5S training equips employees with the skills to identify unnecessary items, arrange tools and equipment efficiently, maintain cleanliness, establish standardized procedures, and ensure sustainability over time.

This lean management technique goes beyond initial setup. It encourages regular audits and continuous improvement, fostering a culture of orderliness and efficiency. Process standardization is achieved through visual management, clear documentation, and consistent application of the 5S principles. This approach not only improves productivity but also enhances safety, reduces waste, and creates an environment conducive to innovation and employee engagement.

Process Standardization: The Key to Consistency and Quality

Process Standardization plays a pivotal role in enhancing productivity and maintaining consistent quality across various industries. At its core, it involves implementing structured systems and procedures that ensure every task is executed in a predefined, efficient manner. This concept is deeply rooted in lean management principles, which emphasize minimizing waste and maximizing value through continuous improvement.

One powerful tool in this regard is the 5S training methodology—a set of principles aimed at workplace organization. The ‘5S’ stands for Sort (organize items), Set in Order (arrange them logically), Shine (clean and maintain), Standardize (document processes), and Sustain (continuously improve). By adopting these practices, organizations can streamline their operations, reduce errors, and boost employee efficiency. Process standardization ensures that everyone follows the same steps, leading to predictable outcomes and a more controlled production environment. This, in turn, enhances overall productivity by eliminating time-wasting activities and promoting a culture of continuous improvement.