The 5S methodology is a lean management tool transforming chaotic workspaces through structured sorting, setting in order, cleaning (shining), standardizing, and sustaining practices. It minimizes waste, streamlines processes, boosts productivity, enhances employee morale, and promotes continuous improvement, ultimately driving organizational success in today's competitive business environment.

Discover the power of structured housekeeping practices with our comprehensive guide. Explore foundational techniques like the 5S methodology—a proven system for fostering order and efficiency. Learn how to integrate lean management principles into daily routines, enhancing productivity across your workspace. Uncover versatile tools and organization techniques tailored for optimal performance. Finally, grasp the essence of continuous improvement through standardized processes, ensuring long-lasting organizational excellence.

- Understanding the 5S Methodology: A Foundation for Order

- Implementing Lean Management Principles in Daily Routines

- Workplace Organization: Tools and Techniques for Efficiency

- Continuous Improvement Through Standardized Processes

Understanding the 5S Methodology: A Foundation for Order

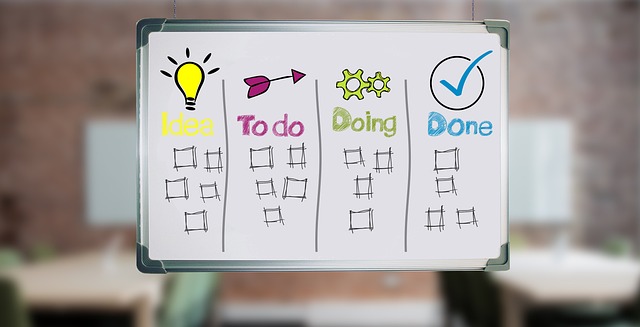

The 5S Methodology is a powerful tool in the realm of workplace organization and lean management, offering a structured approach to creating an efficient and orderly environment. This method, at its core, focuses on eliminating chaos and waste, fostering a culture of continuous improvement. The ‘5S’ stands for Sort, Set in Order, Shine, Standardize, and Sustain, each step building upon the previous one like the strands of a tapestry.

With 5S training, employees learn to sort through their workspace, removing unnecessary items and keeping only what is essential. This process lays the foundation for setting everything in its designated order, ensuring an organized layout that enhances productivity. Regular ‘shining’ or maintenance keeps the area clean, while standardization guarantees consistent processes and practices. Finally, sustainability ensures these improvements are maintained over time, creating a lasting impact on workplace efficiency and employee morale.

Implementing Lean Management Principles in Daily Routines

Implementing Lean Management Principles in daily routines is a game-changer for any organization aiming to achieve optimal efficiency and workplace organization. The core concept revolves around adopting practices that minimize waste, streamline processes, and enhance productivity. One proven method is the 5S training methodology, which stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This system encourages employees to regularly review their workspace, keeping only essential items, organizing them logically, maintaining a clean environment, establishing standardized procedures, and continuously improving these practices.

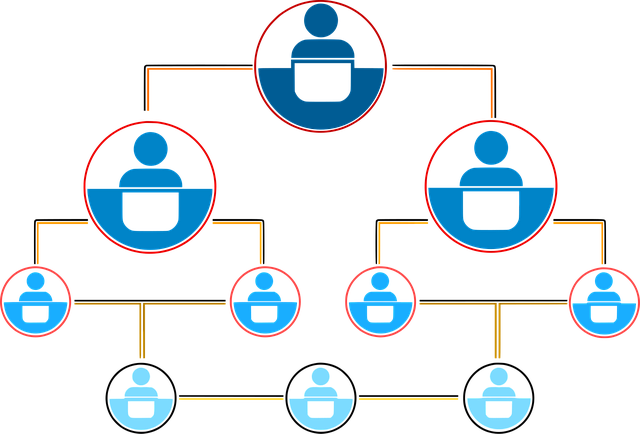

By integrating lean management into daily operations, organizations can achieve remarkable results in workplace organization. Process standardization ensures consistency, reducing errors and wasted time. The 5S continuous improvement approach fosters a culture of ongoing refinement, where teams regularly assess their processes, identifying areas for enhancement. This not only optimizes workflow but also empowers employees to take ownership of their roles, contributing to a more engaged and productive workforce.

Workplace Organization: Tools and Techniques for Efficiency

In today’s fast-paced business environment, efficient workplace organization is a key driver for improved productivity and overall operational excellence. Implementing structured housekeeping practices, such as 5S training, forms a solid foundation for achieving lean management principles. This systematic approach involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—a continuous improvement cycle that fosters an organized, safe, and productive work environment.

By leveraging 5S continuous improvement methodologies, organizations can streamline processes, minimize waste, and enhance workflow efficiency. Process standardization ensures that tasks are executed consistently, reducing errors and maximizing resource utilization. This level of organization not only benefits individual workers but also contributes to a more cohesive and collaborative team dynamic, ultimately driving organizational success in an ever-evolving market.

Continuous Improvement Through Standardized Processes

In today’s competitive business landscape, continuous improvement is not just an advantage but a necessity. Structured housekeeping practices, built on 5S training and lean management principles, play a pivotal role in achieving this. By implementing process standardization, organizations can create an environment of workplace organization that not only enhances efficiency but also drives sustainable growth.

The 5S continuous improvement methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—serves as a powerful framework. It teaches employees to organize their workspace, maintain cleanliness, and establish standardized procedures. This not only improves productivity but also fosters a culture of quality control and operational excellence. Embracing lean management principles further streamlines processes, identifies and eliminates waste, and ensures that every step in the workflow contributes value, ultimately leading to improved customer satisfaction and competitive edge.