The Visual Workplace promotes workplace efficiency through 5S training, a Lean management framework. This methodology includes sorting, setting in order, cleaning, standardizing, and sustaining to create an organized environment. Adopting 5S leads to significant productivity gains (up to 20%) by eliminating waste and standardizing processes. Continuous improvement, data-driven insights, and employee engagement are key to success. Visual aids and regular audits sustain efficiency in dynamic markets, fostering a culture of ownership and accountability.

In today’s competitive business landscape, effective workplace organization is no longer an option—it’s a strategic imperative. The traditional clutter and inefficiency that plague many work environments not only hinder productivity but also undermine the overall morale of employees. This article delves into the transformative power of Visual Workplace Methodology, particularly leveraging 5S training and lean management principles. By implementing structured processes like 5S continuous improvement and process standardization, organizations can cultivate a disciplined, streamlined workflow that fosters collaboration and drives operational excellence.

- Understanding the Visual Workplace: A Lean Management Approach

- Implementing 5S Training: Organize Your Workspace Effectively

- The Power of Continuous Improvement: 5S and Beyond

- Standardizing Processes: Natural Organization through 5S

Understanding the Visual Workplace: A Lean Management Approach

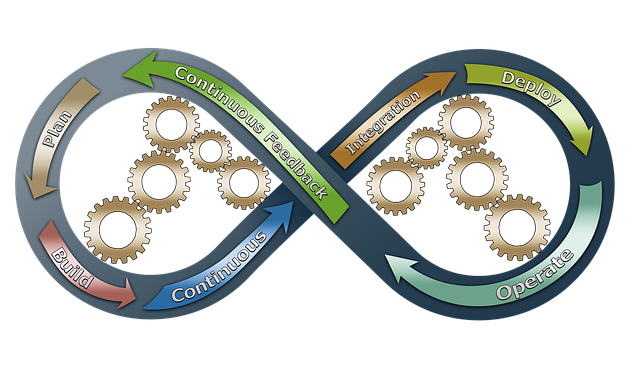

The Visual Workplace: A Lean Management Approach offers a transformative perspective on workplace organization and efficiency. At its core, this methodology emphasizes the power of visual management tools to enhance productivity and create a more streamlined work environment. This concept draws heavily from the principles of Lean management, aiming to eliminate waste, improve processes, and foster continuous improvement. By implementing 5S training—a foundational practice in lean management—organizations can systematically organize their workspace, equipment, and tasks, leading to significant gains in efficiency.

The 5S methodology involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke). Each step builds upon the previous one, creating a culture of order and quality. For instance, sorting involves identifying and categorizing items, keeping only what is essential; setting in order ensures everything has its designated place, facilitating quick access and reducing time wasted searching. Shining emphasizes maintaining cleanliness, which not only improves aesthetics but also prevents equipment issues and accidents. Standardization, through process documentation and training, ensures these practices are consistently followed, while sustaining reinforces the 5S culture through regular audits and employee engagement.

Practical implementation requires a commitment to continuous improvement. Organizations should begin with a comprehensive assessment, identifying areas for improvement and potential waste. Data-driven insights can provide valuable metrics, showing the impact of 5S on productivity and worker satisfaction. For example, a study by the Japan Institute of Plant Maintenance found that companies adopting 5S principles experienced an average 20% increase in production efficiency within six months. Expert advice suggests involving all employees in the process, as buy-in from the workforce is crucial for sustained success. By integrating visual management tools and fostering a culture of organization and discipline, businesses can harness the full potential of their workplace, leading to enhanced performance and competitiveness in today’s market.

Implementing 5S Training: Organize Your Workspace Effectively

The 5S training methodology is a cornerstone of lean management, offering a structured approach to workplace organization and continuous improvement. This system, derived from Japanese manufacturing practices, promotes an environment conducive to efficiency and productivity by eliminating waste and standardizing processes. The ‘5S’ acronym represents five disciplines: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. Each step builds upon the previous one, creating a foundation for streamlined operations.

Implementing 5S training involves a systematic process that begins with sorting through all items in the workspace, removing those that are unnecessary or contribute to inefficiency. This initial phase sets the stage for the remaining steps. For instance, a manufacturing floor might organize tools and materials based on frequency of use, keeping the most essential items within arm’s reach. Once sorted, items are arranged methodically, ensuring every tool has its designated place. Regular cleaning and maintenance, represented by the ‘Shine’ step, become second nature as employees take ownership of their organized space. Standardization is achieved through consistent application of these principles, fostering a culture of process improvement where every employee plays a role in maintaining order.

A successful 5S implementation requires commitment from all levels of an organization. Management must prioritize training and support while empowering employees to suggest improvements. Data shows that companies adopting lean management practices, including 5S, experience significant reductions in waste, lead times, and defect rates. For instance, a study by the Lean Enterprise Institute revealed that over 90% of lean implementation projects result in measurable improvements in key performance indicators within six months. To ensure sustainability, regular audits and ongoing training sessions are essential, allowing for continuous refinement and adaptation to changing needs. By embracing 5S training, organizations can transform their workspaces into dynamic, efficient systems that drive success in today’s competitive markets.

The Power of Continuous Improvement: 5S and Beyond

The relentless pursuit of efficiency and effectiveness in workplace operations has birthed numerous methodologies, with Visual Workplace being a standout approach. At the heart of this methodology lies the powerful concept of continuous improvement, which finds its roots in lean management principles. Among the arsenal of tools available, 5S training stands out as a game-changer in workplace organization and process standardization.

The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is a structured framework designed to transform cluttered and chaotic workspaces into streamlined, visually appealing environments. It encourages employees to actively participate in the improvement process by fostering a culture of ownership and accountability. For instance, a manufacturing facility that implements 5S training may see significant reductions in downtime due to equipment misplacement or accessibility issues. A study conducted by the International Journal of Production Research revealed that companies adopting lean management practices, including 5S, experienced an average 20% increase in productivity over two years.

Continuous improvement, however, extends beyond 5S training. It involves a systematic review and optimization of every aspect of the workplace, from workflow design to inventory management. Organizations should regularly conduct root cause analysis to identify recurring issues, implement process adjustments, and measure the impact of changes. For example, a logistics company might streamline its receiving process by standardizing packaging types and implementing a digital tracking system for shipments, leading to reduced handling times and improved order accuracy rates. By naturally integrating these improvements into the daily routine, companies can ensure sustainability and long-term success.

To harness the full potential of 5S and continuous improvement, organizations must invest in comprehensive 5S training for all employees. This involves clear communication of goals, hands-on practice, and ongoing support. Regular audits and visual management tools, such as color-coded labeling and process flow diagrams, can serve as powerful reminders and motivators for maintaining an organized workplace. Ultimately, embracing a culture of continuous improvement enables businesses to stay agile, responsive, and competitive in today’s dynamic market.

Standardizing Processes: Natural Organization through 5S

Visual workplace methodologies are transformative tools that revolutionize how we approach workplace organization and efficiency. Among these, Standardizing Processes through 5S stands out as a powerful lean management technique, enabling organizations to achieve exceptional levels of productivity and quality. The 5S framework—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is more than just a set of steps; it’s a holistic approach that cultivates a culture of continuous improvement.

The heart of this methodology lies in process standardization, which naturally emerges as employees embrace the 5S principles. Through rigorous 5S training, workers learn to identify and eliminate waste, organize their workspace with precision, and maintain this order consistently. For instance, a manufacturing floor that implements 5S can witness a significant reduction in downtime due to equipment searches, as every tool and component finds its designated place. Data from lean management studies shows that standardized processes lead to 20-30% increased productivity over time, making 5S continuous improvement an invaluable asset for any organization striving for operational excellence.

Practical application begins with a comprehensive sorting exercise, where unnecessary items are discarded or repurposed, leaving only essential tools and materials. Following this, setting things in order involves creating logical layouts and assigning specific locations for each item. Regular cleaning and maintenance, or the ‘shine’ step, ensure that the workspace remains organized and safe. Standardization is achieved through established protocols, clear documentation, and ongoing training, fostering a culture where every employee takes pride in their role within the process. Finally, sustaining these improvements requires regular audits, continuous feedback, and a commitment to incremental adjustments based on performance data.

To realize these benefits, organizations must invest in comprehensive 5S training programs tailored to their specific needs. Engaging all levels of employees ensures buy-in and encourages a proactive approach to workplace organization. By standardizing processes naturally through 5S, companies can not only enhance operational efficiency but also foster a sense of ownership and accountability among their workforce.