Implementing 5S training in lean management revolutionizes work environments by promoting productivity and satisfaction through systematic organization. This method, comprising sorting, setting in order, shining, standardizing, and sustaining, creates efficient workspaces that streamline processes, reduce waste, and encourage continuous improvement. By fostering a culture of quality and standardization, 5S training boosts employee engagement and drives organizational success through regular reviews and data analysis. Process standardization transforms chaotic environments into structured operations, enhancing productivity, safety, and overall efficiency.

In today’s dynamic business landscape, a structured work environment is paramount for enhancing productivity and efficiency. This article explores the concept of a well-organized workplace, delving into essential elements like 5S training, Lean management principles, and process standardization. We’ll uncover how these strategies, including 5S continuous improvement, transform chaotic spaces into streamlined operations. By implementing best practices, businesses can unlock significant benefits, fostering a culture of excellence and continuous growth.

- Understanding the Concept of a Structured Work Environment

- The Role of 5S Training in Workplace Organization

- Lean Management Principles and Continuous Improvement

- Process Standardization: Enhancing Efficiency and Effectiveness

- Benefits and Best Practices for Implementing Structured Work Environments

Understanding the Concept of a Structured Work Environment

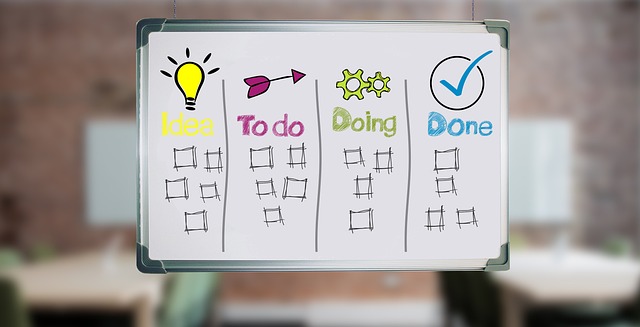

A structured work environment is a well-organized and optimized space designed to enhance productivity, efficiency, and overall employee satisfaction. It involves implementing systematic practices like 5S training (a lean management technique) to ensure every aspect of the workplace is systematically arranged and maintained. The ‘5S’ method stands for Sort, Set in Order, Shine (or clean), Standardize, and Sustain, creating a visually appealing and highly functional workspace.

This concept goes beyond mere aesthetics; it encompasses workplace organization and process standardization as key components of continuous improvement initiatives. By promoting order and consistency, a structured environment reduces waste, streamlines workflows, and fosters an atmosphere conducive to focused work. It encourages employees to follow established processes, making tasks more predictable and efficient while fostering a culture of quality and ongoing enhancement.

The Role of 5S Training in Workplace Organization

The Role of 5S Training in Workplace Organization

In today’s competitive business landscape, efficient and organized workplaces are key to achieving operational excellence. This is where 5S training comes into play as a powerful tool within lean management strategies. By focusing on sorting, setting in order, shining (cleaning), standardizing, and sustaining, 5S training facilitates the creation of an optimized work environment. It involves a systematic approach to workplace organization that not only enhances productivity but also improves overall employee satisfaction.

This method, rooted in Japanese manufacturing practices, promotes process standardization and continuous improvement. By teaching employees to maintain a clean, well-arranged workspace, reduce waste, and streamline processes, 5S training empowers teams to take ownership of their environment. This, in turn, leads to increased efficiency, reduced errors, and improved safety, ultimately contributing to the success and competitiveness of any organization.

Lean Management Principles and Continuous Improvement

In a structured work environment, Lean Management Principles and Continuous Improvement go hand in hand to enhance efficiency and productivity. At the heart of this approach lies 5S training—a systematic method that promotes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these principles, teams can achieve a visually appealing and streamlined workspace, which directly translates to improved workflow processes. This visual management technique not only enhances productivity but also fosters a culture of continuous improvement.

Continuous Improvement, or Kaizen, involves identifying inefficiencies and implementing small, incremental changes to optimize processes. Process standardization is key here, ensuring that tasks are performed consistently without unnecessary steps. This approach encourages employees to suggest improvements, fostering a sense of ownership and engagement. Regular reviews and data analysis play a crucial role, allowing teams to measure progress, identify bottlenecks, and make data-driven adjustments, ultimately driving organizational success in a structured work environment.

Process Standardization: Enhancing Efficiency and Effectiveness

Process Standardization plays a pivotal role in transforming a chaotic work environment into a structured and efficient one. By implementing Lean Management principles, organizations can streamline their operations, eliminating unnecessary steps and reducing waste. This is where 5S training becomes an invaluable asset. The ‘5S’ methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—is a proven approach to workplace organization. It encourages employees to maintain a tidy, well-organized space, ensuring that tasks are performed consistently and effectively.

Through process standardization, companies can achieve remarkable efficiency gains. Each step of a workflow is clearly defined, making it easier for new hires to get up to speed quickly. This standardization also facilitates continuous improvement; as processes are regularly reviewed, inefficiencies can be identified and addressed, leading to ongoing enhancements in productivity and quality.

Benefits and Best Practices for Implementing Structured Work Environments

Implementing a structured work environment offers numerous advantages for businesses and employees alike. By embracing principles like lean management and process standardization, organizations can enhance productivity, improve efficiency, and create a safer workplace. The 5S training method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is a powerful tool within this framework. It promotes an organized space, reduces waste, and fosters a culture of continuous improvement, enabling employees to work more effectively and with greater satisfaction.

Best practices for structured work environments include engaging all team members in the process, ensuring regular reviews to adapt to changing needs, and integrating 5S principles into daily operations. Incorporating these strategies facilitates seamless workflow, reduces errors, and enhances overall job performance. Effective workplace organization also allows for better inventory management, easier access to resources, and improved safety by eliminating clutter and potential hazards.