Operational workflow standardization through 5S training and lean management boosts efficiency, reduces waste, and enhances productivity. The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) organizes workspaces and standardizes procedures, benefiting manufacturing and retail sectors. Lean tools like Kaizen events and value stream mapping visually map workflows, identifying improvements. Regular 5S training fosters continuous learning, leading to significant gains in productivity, customer satisfaction, and competitiveness through disciplined workplace organization and sustainable continuous improvement.

In today’s competitive business landscape, operational efficiency is a cornerstone of success. However, disorganized workflows can hinder productivity, leading to errors, wasted time, and resources. This challenge is where operational workflow standardization steps in as a powerful solution. By implementing 5S training and lean management principles, organizations can transform their workplaces into models of organization and efficiency.

The problem lies in ad-hoc processes that often create chaos and confusion. To address this, continuous improvement through 5S methodologies offers a systematic approach. This involves sorting, setting in order, shining a light on the workspace, standardizing, and continually reviewing—a process that naturally drives workplace organization and enhances productivity.

- Understanding Operational Workflow Standardization

- Implementing 5S Training for Workplace Organization

- Sustaining Continuous Improvement through Lean Management

Understanding Operational Workflow Standardization

Operational workflow standardization is a strategic process aimed at enhancing efficiency, reducing waste, and improving overall productivity within an organization. Understanding this concept involves delving into methodologies like 5S training and lean management that prioritize workplace organization and continuous improvement. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—is a proven approach to streamline operations by eliminating clutter, establishing clear processes, and fostering a culture of discipline. For instance, a manufacturing facility implementing 5S principles can significantly reduce downtime and increase production capacity through systematic organization of the workspace and standardizing work procedures.

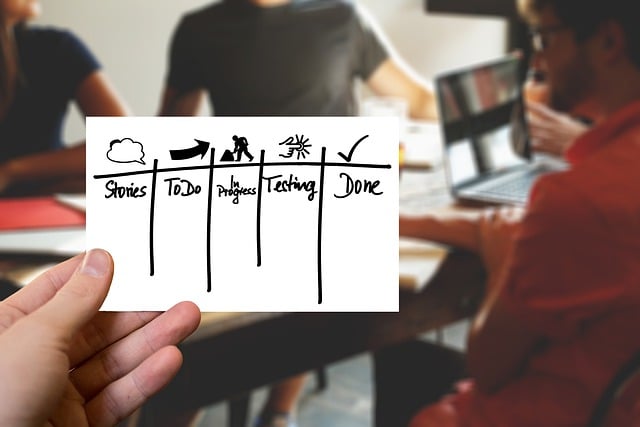

Process standardization naturally flows from effective 5S practices, focusing on documenting and refining workflows to ensure consistency and quality. This involves identifying each step in a process, analyzing its value, and eliminating or improving non-value-added activities. Lean management principles, including Kaizen events and value stream mapping, play a pivotal role in this process by visually representing workflows and identifying areas for improvement. For example, a retail store employing lean techniques can optimize inventory management, reduce customer wait times, and enhance overall store efficiency through standardized processes and continuous refinement.

Expert perspectives emphasize the importance of engaging all levels of the organization in workflow standardization efforts. This collaborative approach ensures that frontline employees, who often possess valuable insights into daily operations, are actively involved in identifying inefficiencies and proposing solutions. Regular 5S training sessions and lean management workshops can empower workers to take ownership of process improvement, fostering a culture of continuous learning and enhancement. By implementing these strategies effectively, organizations can achieve remarkable gains in productivity, customer satisfaction, and overall competitiveness in their respective industries.

Implementing 5S Training for Workplace Organization

Operational workflow standardization is a critical component of lean management, aiming to enhance efficiency and productivity through process streamlining and workplace organization. One proven methodology for achieving this is the implementation of 5S training, rooted in Japanese manufacturing principles. 5S—sort, set in order, shine, standardize, and sustain—is a continuous improvement framework that transforms cluttered workspaces into streamlined environments, fostering a culture of discipline and efficiency.

The impact of 5S training extends beyond immediate physical changes. By encouraging employees to question every aspect of their workflow, it promotes a mindset shift towards continuous improvement. For instance, a manufacturing plant adopting 5S principles may initially organize tool storage, but over time, workers might identify inefficiencies in production lines, leading to further process standardization and significant operational enhancements. Data from case studies suggests that companies implementing 5S can experience up to 20% increase in productivity and reduced waste by 30%.

Practical application begins with a thorough sorting exercise, eliminating unnecessary items from the workplace. This step alone can significantly reduce clutter, enhancing safety and accessibility. Subsequently, setting things in order involves establishing logical storage systems, ensuring every item has its designated place. Regular training sessions and clear communication are vital to maintaining this order. The ‘shine’ phase encourages visual management techniques, making it easy to identify issues or inefficiencies. Standardization is achieved through consistent application of the 5S principles, fostering a culture of adherence to best practices. Finally, sustainability requires ongoing commitment and participation from all levels of the organization, reinforcing the benefits of 5S training as an integral part of workplace culture.

Sustaining Continuous Improvement through Lean Management

Operational workflow standardization is a cornerstone of modern business efficiency, with lean management as its driving force. At the heart of lean management lies a relentless pursuit of eliminating waste and maximizing productivity, principles that are systematically implemented through practices like 5S training. This organized approach involves sorting, setting in order, shining a light on (seifuken), standardizing, and sustaining (shitsuke), creating an environment conducive to continuous improvement.

Workplace organization achieved through 5S not only enhances visibility and accessibility of tools and materials but also fosters a culture of discipline and engagement among employees. By systematically applying these principles, organizations can identify and eliminate non-value-added steps in processes, leading to significant time and cost savings. For instance, a manufacturing facility implementing 5S found a 30% reduction in production time for one key assembly line within six months, showcasing the tangible benefits of streamlined workflows.

However, sustaining continuous improvement is not merely a one-time initiative; it requires ongoing commitment and structured processes. Regular audits, employee involvement, and ongoing training on 5S principles are essential to maintain momentum. Organizations that integrate lean management into their DNA, where 5S becomes second nature, can expect to see consistent improvements in overall operational efficiency, quality, and customer satisfaction. This holistic approach ensures that process standardization is not just a temporary fix but a dynamic, evolving system capable of adapting to changing market demands.